Ensure that the sampling tube is angled downward from the duct smoke detector to allow for moisture drainage away from the detector.

Duct smoke detector sampling tube installation.

To ensure correct operation install the superduct duct smoke detector using the following guidelines.

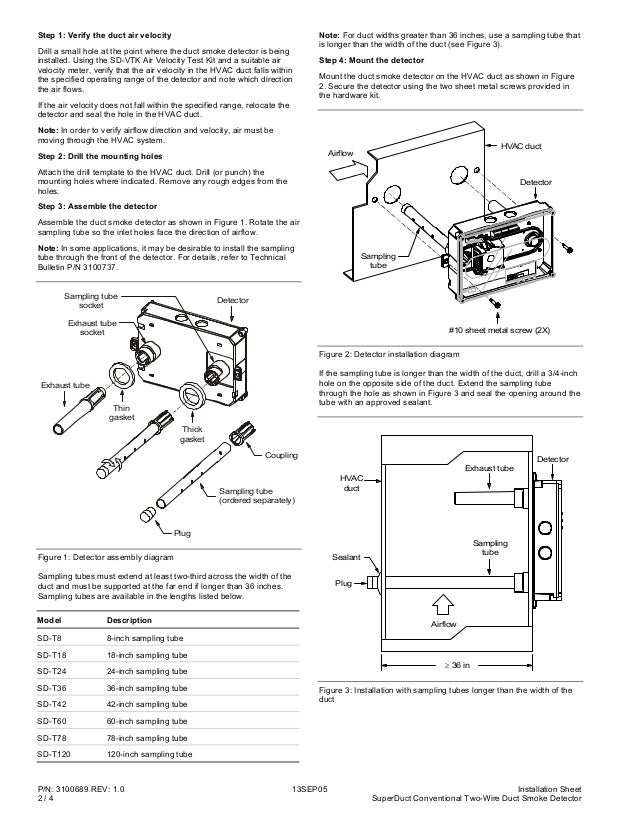

Air is introduced to the duct smoke detector s sensing chamber through a sampling tube that ext ends into the hvac duct and is directed back into the ventilation system through an exhaust tube.

Locate the sensor so its sampling tube is positioned in a straight length of square duct between six and ten duct widths from any bends or obstructions as shown in the diagram below.

Once any sampling tube length adjustments are made plug the end of the sampling tube with the provided end cap.

The difference in air pressure between the two tubes pulls the sampled air through the sensing chamber.

3 contents of the duct smoke detector kit 1.

Ensure that the sampling tube is angled downward from the duct smoke detector to allow for moisture drainage away from the detector.

Sampling tube connectors are equipped with set screws which allow the tubes to be mounted only in directions shown in figure 2.

Move duct housing sampling tube assembly to desired location.

Use 4 mounting screws 4 12 x 1 2 sheet metal screws packaged in installation kit to secure the housing to the air duct.

Sampling tubes install from front and rear compatible with existing accessories able to address detector per code switches on sensor head.

Sampling tube assembly see figure 2 the duct detectors are designed for use in ducts where the air velocities are from 300 to 4000 feet per minute.

The sampling tube end cap included with the detector is critical to proper operation of the duct smoke detector.

Drill a 3 4inch hole in the duct opposite the hole already cut for the sampling tube.

Verify this by checking specifications of installation and if necessary use an alnor model 6000p velocity meter or equivalent to check the air velocity.

Drilling template 4.

Duct smoke detector a.

Sensor power board assembly and covers sensor head is factory installed 2.

Drill a 3 4inch hole in the duct opposite the hole already cut for the sampling tube.

The sampling tube should be angled at least 1 4 downward for every 12 of duct width per figure 4.

Three 10 sheet metal screws for mounting 3.