For the longest time i have been told and have seen in the field static pressure sensors controlling vortex or vfd located at the fan discharge or downstream of the duct before any take offs.

Duct static pressure sensor location.

Sensors located above a ceiling tend to get lost and forgotten.

More who we are.

The recommended frequency of data collection is between 5 and 30 minutes.

Air pressure sensors surge dampeners.

For the longest time i never questioned this logic.

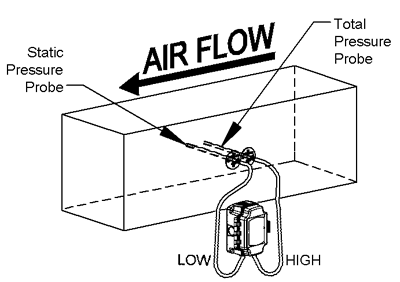

Run two 1 4 inch sensing lines high and low to the sensing location.

I would pick a point in the longer duct because that is more likely to be the duct run that set the fan system static.

Locate the static pressure sensor at the panel.

Location mount the static pressure probe on the duct plenum or air handler to allow exposure to the average airflow.

So you might select 2 3 of the physical distance down that duct.

Avoid locations where air stratification can cause changes in airflow.

Two thirdsthe distancefrom the supply fan to the end of the.

This will allow for effi cient operation figure 1 even if the reset logic has failed due to a rogue zone or other problem.

Duct static sensors a300 series rps sd 01 21121 60681.

Once the sensor is installed you could fine tune the set point there as necessary to ensure that you had adequate pressure everywhere else.

Is there a reset schedule for the duct static pressure.

When analyzing the static pressure the trends to look for include.

Kele overview 24 product categories line card 300.

In many systems the first locationis.

The pressure is measured by the sensor p located approximately 2 3rdof the way down the main duct starting air handling unit.

Choose a static pressure sensor that allows the hvac controller to operate in the upper half of the sensor s normal operating range.

Locate the static pressuresensor for modulatingfan.

As the zone dampers throttle back the duct pressure rises and the fan is controlled to reduce the duct pressure.

Capacity out in the supply duct system not at the fan.

Duct static pressure transmitter.

The sensor is field installed and the controller is set to maintain the duct.

For the same reason the static pressure sensor should be located as far out into the duct system as is practical so that the high end of the setpoint range 1 3 in.

The most commonly recommended static pressure sensor location is a point in the supply duct at which the duct static pressure at design flow is approximately two thirds of the duct static pressure drop from the fan outlet to the terminal unit inlet.

Is the static pressure set point too high or too low.

Multi range differential zone pressure transmitters.

325 pa in this example can be as low as possible.