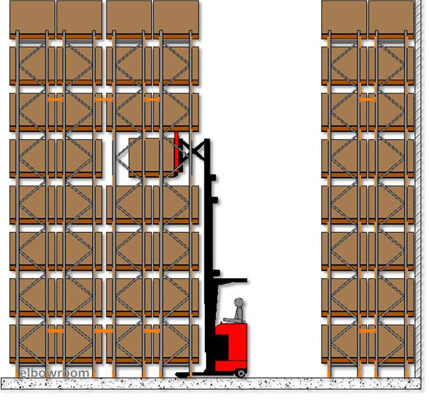

This type of racking reduces the amount of accessible stock keeping units sku s due to 50 of sku s being behind pallets when storage locations are.

Double deep pallet racking dimensions.

Although the main advantage of the double deep system i e the ability to save space due to the need.

Ideal for businesses with a minimal range of.

Pallet access lifo double deep is last in first out lifo.

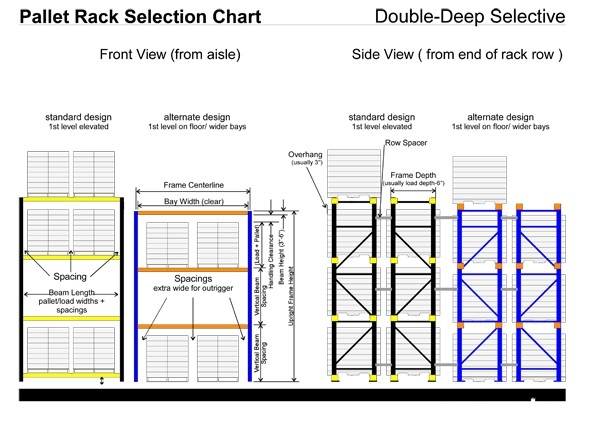

Stand up rider narrow aisle double reach or deep reach forkliftswill require an aisle width of approximately 10 feet for standard 48 long pallets with loads for placing and storing on standard racking at a right angle.

Ridg u rak double deep pallet rack systems place one row of 100 selective pallet rack behind another.

Similar to drive in racking this system is generally used when storing pallets of the same type and when stock rotation and pick faces are not a major concern.

Store up to four pallets deep for swift dispatch of large single sku orders.

Another pallet is then placed on the front rack unit eliminating the need for an aisle between the two storage racks.

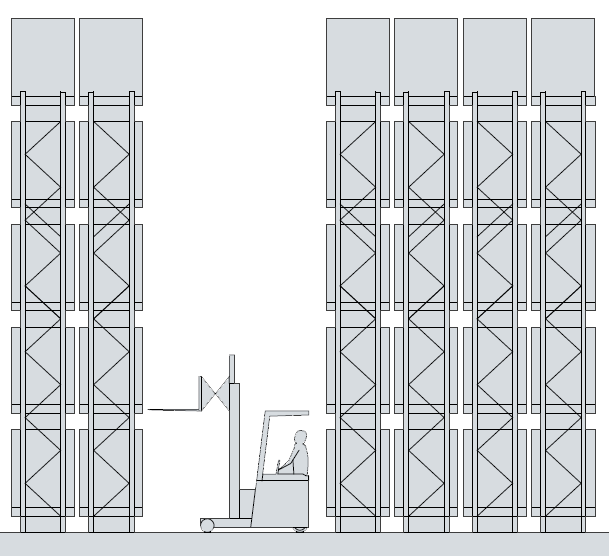

This provides access to two pallets from the same side of the aisle with one placed behind the other towards the back of the pallet rack the illustrations below will give you a better idea of how the load units are arranged.

Practical for high volume single skus required for rapid despatch.

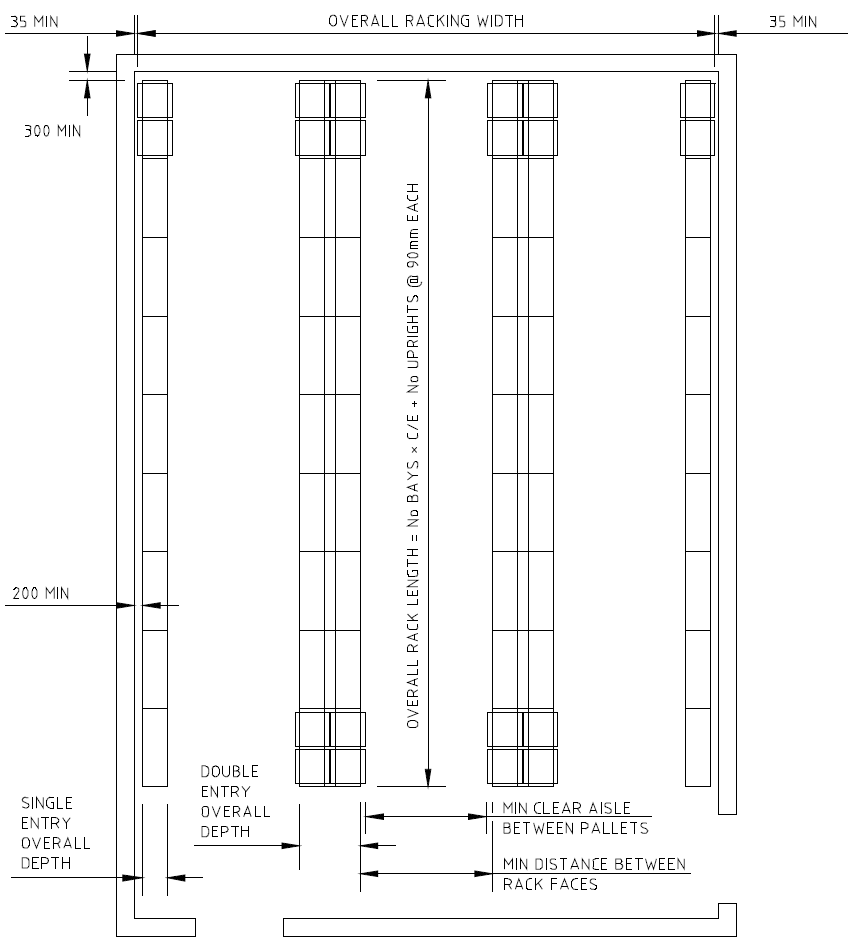

By storing pallets two deep higher storage density can be achieved while operators are still able to access stock easily and relatively quickly.

Pallet racks can be installed in a double deep configuration.

This means a maximum of four rows can be placed back to back.

Double deep racking is two pallet deep configuration pallet racking.

These forklifts have double scissor pantograph allowing for storage and retrieval in two deep standard racking.

Respond to an estimated average of 1 210 fires in make sure your pallets and loads are the right size for the depth of your rack.

The double entry aisle offers easy access through dual pantograph or sliding fork attachments.

Double deep pallet racking is the best compromise between a selective and high density pallet racking system.